1.How to deal with insufficient paint strength?

There are two cases of insufficient paint strength: one is the normal drying strength, and the other is the strength after high temperature erosion. The two are not interchangeable. The normal drying strength is high ≠ high temperature strength, and a misunderstanding will cause an accident.

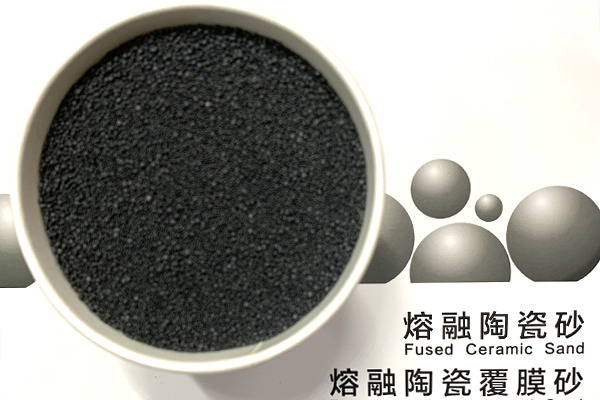

(1) There are three reasons for insufficient drying strength: first, the lack of additive performance, the second is the insufficient amount of additives, and the third is the problem of aggregate powder. The first two are easy to understand, while the latter are not necessarily universally clear. The following focuses on the problem of aggregate powder. ① If the same aggregate powder is too thick or too fine, it will affect the strength of the coating after drying. The selection range is 180-250 mesh. ② Light-weight aggregate powder (light weight) is often not as strong as heavy-weight aggregate powder, because the coating formed by it has a slightly lower density, and its volume and coverage are obviously different under the same weight. ③ Some aggregate powders will seriously weaken the dry strength of the coating because it contains a certain harmful element, such as CaO, MgO, etc. There are even some inexplicable ingredients. The larger the content, the lower the coating strength and the storage time of the slurry. The longer the intensity, the more pronounced the drop in intensity.

(2) Insufficient high-temperature strength is caused by the poor performance of additives. Almost all common foundry coatings have a fatal commonality-they cannot withstand high-temperature erosion for a long time, and they can't stand up to 1600 ℃ for more than 40 seconds. The real solution to this problem is not mainly the fire resistance of the aggregate powder, but the high temperature strength of the additive: and the higher the temperature and the stronger and harder the casting temperature range, this is called high temperature ceramization, which is superior to the high temperature performance of ceramic tubes.