Ceramic Foundry Sand

Category:

keyword:

Ceramic Foundry Sand

- Product Details

- Techspecs

-

Overview of Fused Ceramic Sand:

Ceramic Foundry Sand, also called Ceramsite, fused ceramic sand, is kind of man-made spherical shape ceramic particles made by spraying process from the melting bauxite in an Electric Arc Furnace. The ceramic foundry sand provides a unique combination of spherical shape grain, chemistry, and physical properties that result in numerous performance advantages compared with Silica Sand or Zircon Sand.

lt provides an efficient way in the foundry industry to improve the quality of the casting, reducing the cost and avoiding environmental pollution, lt is also good substitution to Chromite and Zircon sand because of lower price. At present, ceramic foundry sand is acknowledged in the worldwide as the newest and the best ideal sand for the foundries and has a wide feasibility of applications.

Features and Advantages of Fused Ceramic Sand advantages:

1. Solid sphere: The shape of Ceramic Sand is spherical with smooth surface and less surface area and offering a very good flow ability and filling ability. To compare with other sands else, less binder is used at the same mold strength and higher venting ability. It also offers the excellent collapsibility.

2. Lower thermal expansion rate: It makes the dimensions of castings better, less crack and defect and higher output.

3. Lower breakage rate: Ceramic Sand has a higher density and a very lower breakage rate at the reclamation. It makes a better reclamation rate to reduce the waste sand to be favor to the environment.

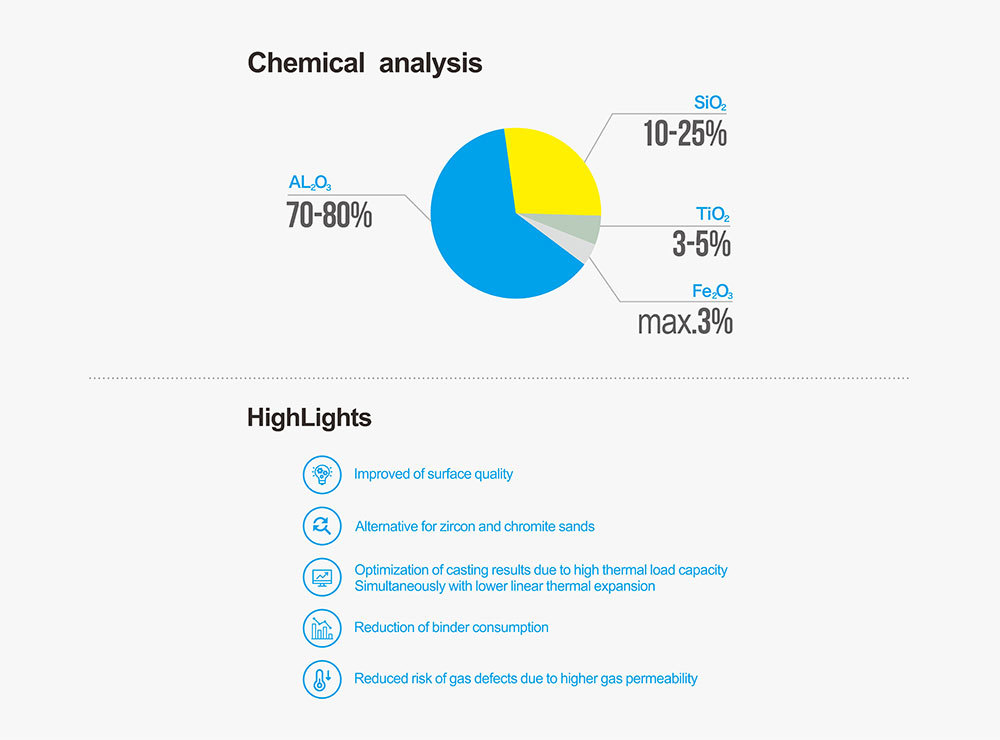

4. High refractoriness: The major chemistry is Al2O3. PH appears neutral. It belongs to the refractoriness of the series of Aluminum and Silicon which has a very good refractory performance. It is suitable for all kinds of metal and alloy castings.

Applications of Fused Ceramic Sand:

Ceramic Foundry Sand also named ( Ceracite, Fused Ceramite, Ceramic Sand), It is made of high quality materials by arc melting from bauxite, our Ceramic Foundry Sand with reasonable price, the price is much better than zircon sand , chromite sand; especially low-expansion, non-sintered, not powder, not crack, sticky sand (to eliminate the negative impact of the cast body mass), regeneration performance, and increase the yield of the casting.

Fused Ceramic Sand can be used as raw materials for some castable, lining material, brick. Especially for large ladle castable, high-middle BF trough castable, gunning mix, precast, etc unshaped refractory materials. Also for some shaped refractory, like: corundum brick, corundum and mullite-corundum sagger, Corundum porous plug brick, whole spray gun, composite nozzle, high temperature kiln's lining.

Comparison among the four commonly used foundry sands:

NAME

Particle Shape

Refractoriness

℃

Reclaimation

rate

Bulk

Density g/cm3

Binder

Amount

Price

Mons’ hardness scale

Thermal Expansion

Environment

Silica sand

irregular

Around 1750

Low

1.4-1.5

cheap

7

High

dust pollution

Fused Ceramic Sand

Very close to sphere:it brings good air permeability&flowability

≥1800

High

1.95-2.05

Less than 30%-50% comparing with other sand

modestly priced

8

Low

environment-friendly

Chromite

Sand

Irregular

1830

Low

2.6-2.7

modestly priced

5.5-6.5

Low

heavy metal pollution

Zircon

Sand

irregular

2340-2550

high

2.9-3.1

Very

expensive

7.5-8

Very low

radioactive pollution

-

Techspecs of Ceramic Foundry Sand:

Spec Mesh 16 20 30 40 50 70 100 140 200 270 Pan AFS Range μm 1180 850 600 425 300 212 150 105 75 53 Pan AFS30 ≤10 25-45 35-55 5-15 ≤5 25-29 Typical Value 3.2 38.6 48.9 9 0.2 26.4 AFS40 ≤5 30-50 25-45 5-20 ≤7 ≤5 35-39 Typical Value 2.3 46.5 32 15 3.9 0.3 37.74 AFS50 ≤5 10-25 25-40 20-35 10-20 ≤10 ≤5 45-55 Typical Value 1.8 22.8 30.7 22.1 13.6 7 2 49.85 AFS60 ≤10 20-35 25-40 15-30 10-20 ≤8 ≤2 55-65 Typical Value 8.3 26.6 29.5 17.8 13.4 4.2 0.2 60.02 AFS65 ≤10 15-30 20-35 10-25 10-25 ≤10 ≤3 60-70 Typical Value 8.4 23.9 25.6 15.7 18.8 6.9 0.7 65.73 AFS90 ≤1 5-20 10-20 15-30 20-35 10-25 ≤8 ≤3 85-95 Typical Value 0.1 15.5 16.3 17.8 25.7 19.7 4.5 0.4 90.32

Get in Touch

Feel free to contact us and our sales team will get back to you as soon as possible.

Related Products

Fused Resin-Coated Ceramic Sand

The Fused Resin-Coated Ceramic Sand manufactured by Qiangxin adopts fully automatic visual production technology, and the heating temperature, feeding time and sand mixing process are accurately controlled, which effectively ensures the reliability of the performance.

Learn MoreFused Ceramic Sand is the custom ceramic particles with a spherical shape, high refractoriness and low thermal expansion being made by spraying the melted calcined bauxite. It provides a very simple but efficient way for the foundry-men to improving the quality of the castings, reducing the production cost and avoiding environmental pollution, because of that it has the higher price ratio comparing with Chromite sand and Zircon sand. At the present, it is acknowledged in the worldwide as the newest and the best ideal sand for the foundries and has a very wide feasibility of applications for the future development.

Learn More