Copyright © 2019 Sanmenxia Qiangxin Foundry Material Co., Ltd. 豫ICP备19038098号-1 Powered by www.300.cn 豫公网安备 41122102000171号

Product Center

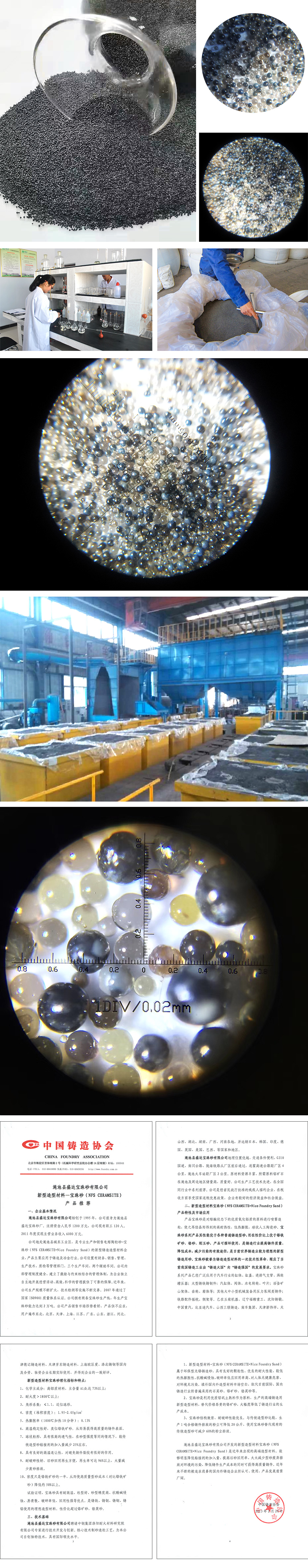

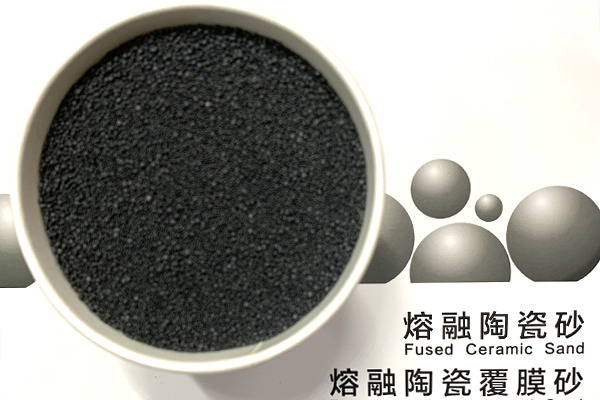

Ceramic Sand Introduction

particles with a spherical shape,

high refractoriness and low thermal

expansion being made by spraying

the melted calcined bauxite.

Ceramic Sand is the custom ceramic particles with a spherical shape, high refractoriness and low thermal expansion being made by spraying the melted calcined bauxite. It provides a very simple but efficient way for the foundry-men to improving the quality of the castings, reducing the production cost and avoiding environmental pollution, because of that it has the higher price ratio comparing with Chromite sand and Zircon sand. At the present, Ceramsite is acknowledged in the worldwide as the newest and the best ideal sand for the foundries and has a very wide feasibility of applications for the future development.

Ⅰ. Ceramsite Major Specification

1.Shape: Sphere

2.Angle Factor: ≤1.1, very spherical

3.Bulk Density: 1.95-2.05 (g/cm3)

4.Refractoriness: ≥1800℃

5.Thermal expansion: 0.13% (10 minutes at 1000℃)

6.Main Chemical composition (representative value):

|

Composition |

Al2O3 |

FeO3 |

SiO2 |

TiO2 |

CaO |

MgO |

K2O |

Na2O |

|

% |

72.36 |

2.16 |

19.72 |

3.23 |

0.43 |

0.35 |

0.33 |

0.08 |

Ⅱ. Fused Ceramic Sand advantages are as follows

1. Solid sphere: The shape of Ceramic Sand is spherical with smooth surface and less surface area and offering a very good flow ability and filling ability. To compare with other sands else, less binder is used at the same mold strength and higher venting ability. It also offers the excellent collapsibility.

2. Lower thermal expansion rate: It makes the dimensions of castings better, less crack and defect and higher output.

3. Lower breakage rate: Ceramic Sand has a higher density and a very lower breakage rate at the reclamation. It makes a better reclamation rate to reduce the waste sand to be favor to the environment.

4. High refractoriness: The major chemistry is Al2O3. PH appears neutral. It belongs to the refractoriness of the series of Aluminum and Silicon which has a very good refractory performance. It is suitable for all kinds of metal and alloy castings.